Seal Test / Sealing Test commercial|seal testing methods pdf : purchasing Our highly respected jet engine seals are widely used in commercial and aerospace engines and include metal E-rings, metal C-rings, metal O-rings and AS1895 seals. . With our extensive and integrated line of seals and sealing .

Economia - DeFato.com - Mossoro

{plog:ftitle_list}

16 de abr. de 2020 · Aprenda a usar um cartão para fechar o beck e fazer a virada sem dobrar o papel. Veja também dicas de redução de danos e outras técnicas de bolação.

Seal strength test methods evaluate the integrity of seals on various types of packaging, from food containers to medical supplies. These tests measure the force required to separate .Testing the integrity of package seals helps ensure that food packaging provides required product protection. Sustainable packaging alternatives, lower cost packaging, and variations in production line sealing parameters are frequently .

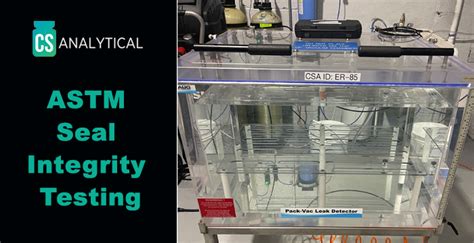

ASTM F88 is a test method in which packaging engineers can define seal strength requirements, like a minimum seal strength. We define .The answer lies in seal strength testing—a critical process in quality control for packaged goods. Seal strength test methods evaluate the integrity of seals on various types of packaging, from food containers to medical supplies. . The duration of the sealing process significantly affects seal strength: Sealing time must be sufficient to . After the test runs, the sealing edges and the shaft surfaces are comprehensively analyzed and measured. . In retarder breaking systems for commercial vehicles, radial lip seals are exposed to .Our highly respected jet engine seals are widely used in commercial and aerospace engines and include metal E-rings, metal C-rings, metal O-rings and AS1895 seals. . With our extensive and integrated line of seals and sealing .

RDM Test Equipment offers quality testing solutions for packaging and material testing. . of jaw temperature, pressure and time to find an optimal balance of material specification, packaging machine speed and seal integrity. Setting these variables incorrectly in production is a costly business in immediate waste, spoilage and customer .Results: The force required to peel a unit width of seal is correlated with sealing temperature to compare the seal strength of one packaging material against another, or against historical data. Limitations: Set points for temperature, pressure, and dwell time are typically standardized to ensure repeatability and inter-lab correlatability.This high performance sealer was designed for high traffic applications; it has a high percentage of solids and can achieve even stronger results with multiple coatings. E10 Epoxy™ will not chip, soften, peal or de-laminate in the presence of water vapor emission, alkalinity, and relative humidity. The chemistry remains resistant to extreme alkalinity (up to 12.5-14pH) when applied .

This lightweight vacuum sealer did a good job achieving a tight seal and reliably kept all wet and dry foods in airtight conditions for months. It offers some customization, as we used the “extended” button to suck out additional air. . *All products reviewed by America’s Test Kitchen are independently chosen, researched, and reviewed .sealing cycle but prior to the temperature of the seal reaching ambient. Refer to Test Methods F1921. 3.1.6 seal initiation temperature, n—on a heat seal curve, the sealing temperature/dwell pressure at which heat seal strength first begins to trend upward from zero heat seal strength. 3.1.7 sealing interface, n—the interface of the two web Long Sous Vide/Seal Test: We sealed five bags (each filled with one new, dry kitchen sponge and 1/3 cup neutral oil) to see how each vacuum sealer did with wet ingredients subjected to a very high temperature for a prolonged period of time. We weighed the sealed bag before testing and then placed the bags in a water bath set to 197°F (using an .

seal testing techniques pdf

The easiest to do is hot water seal. Use distilled or demineralised water with a conductivity below 150 microsiemens and a pH of about 6 (5.5-6.5 is not uncommon). . The sealing test is also described by BS EN 12373-6. I don't know if it is exactly the same as the ASTM, I haven't carried out any gap analysis to find out.Seal tests ISO11607-2 (Validation requirements for forming, sealing and assembly processes), requires Operational Qualification (OQ) of packaging devices to be carried out and documented. The OQ is requiring providing proof of: Intact seal for a specific seal width No channels or open seals No punctures or tears in seals No material delaminating or separation The OQ needs to

Built with a heavy-duty stainless-steel design, this edge sealer with a 11-inch bar is perfect for your small business or personal kitchen. Using a commercial quality pump and built-in cooling fan, this machine not only vacuum seals all bags, but can easily seal multiple times without overheating.

codes mandate even more stringent air sealing and tightness testing requirements. The building’s air leakage rate is quantified by testing. The most common air tightness test is typically referred to as a “blower door” test (page 2). The test equipment consists of a calibrated fan, a panel to seal off the door, and a flow and pressure .

Sealing Temperature, Dwell Time and Sealing Pressure. Heat seal test is to determine the suitable sealing parameters (sealing temperature, dwell time and pressure) for materials. Complies with ASTM F2029 - Standard Practices for Making Heatseals for Determination of Heatsealability of Flexible s as Measured by Seal Strength.

Product Description. Pouch Seal Integrity Test : Designed to test the integrity of seals on either paper/poly or Tyvek® /poly packaging material, the Pouch Seal Integrity Test checks for an intact seal, punctures, tears and open . There are a lot of steps involved in taking on a tiling project - from choosing the perfect material, perfecting your layout, and laying your tile! Sealing tile and grout is a necessary part of the process to protect the materials and .In commercial buildings, many of the electrical boxes and assemblies you’ll need to seal will be on the exterior or exposed to areas without climate control. . apply a small bead to a test surface and note its expansion over a few minutes. Trim .

In depth review and demonstration of the Vevor chamber vacuum sealer. I am really loving this machine!Vevor Chamber Vacuum Sealer DZ-260A: https://amzn.to/4.only the maximum hot seal strength achievable by each material and the sealing temperature required, but also the breadth of the sealing temperature range at any specified level of hot tack. 3.1.11 sealing temperature, n—maximum temperature reached at the interface between the two web surfaces being sealed, during the dwell time of the .ASTM C1265 -94(2005)e1 Standard Test Method for Determining the Tensile Properties of an Insulating Glass Edge Seal for Structural Glazing Applications This test method covers a laboratory procedure for quantitatively measuring the tensile strength, stiffness, and adhesion properties of insulating glass edge seals that are used in structural .

CR tested seven vacuum sealers from six brands. The sealers, roughly to 0, are about as wide as a toaster oven, though most aren’t that tall or deep.The larger models store a roll of .The test procedure may be used to test seals of alternate size and design or using alternative media but such deviations shall be detailed separately on the report form and the results shall not be used to determine the minimum operating temperature of seals .6. Seal test fixture capabilities Bench testing of rotary shaft seals Figure 2 shows the standard horizontal shaft test fixtures that are used to perform much of our instrumented rotary seal testing. These bench test fixtures are capable of testing seals up to 5” (127 mm) in diameter against various environments.

package inflation seal strength test. In the Creep Test, a whole package is inflated to a constant pressure, which is then held for a specified time, resulting in a pass/fail result (see Figure 5). Early users of the method for peelable seals used the test as an analogy for the pressure difference on the seals seen in the ETO Glaze ‘N Seal Olé Mexican Tile Sealer – This Glaze ‘N Seal product provides water-based protection for your porous Saltillo tiles allowing them to resist oil, food, and grease stains. It provides a high gloss aesthetic, and it can be applied to tile indoor or outdoor. . Before using your Saltillo tile sealer on your entire floor, test . A generic solid oxide fuel cell stack test fixture was developed to evaluate candidate materials and processing under realistic conditions. A NiO–YSZ anode-supported YSZ electrolyte cell with a composite cathode was used to evaluate the long-term stability of a sealing system, alumina coating, Ce-modified (Mn,Co)-spinel coating, ferritic stainles steel AISI441 .

To meet the sealing requirements of flat cable with two cores, two cable sealing test specimens were designed and tested, and a scheme of cable sealing structure that can seal the non-circular cross-section cables has been proposed, providing support for developing the cable sealing component applicable to the conductive slip ring of EDS.

seal testing techniques

kibbe test soft gamine

killing me softly with his song traduzione testo italiano

killing them softly shotgun test

seal testing methods pdf

JK8Asia is the biggest online entertainment platform in Asia which running in Malaysia, Singapore, Thailand, Indonesia, Vietnam, Myammar. Fast deposit, Fast withdraw, Fast service 24 hour

Seal Test / Sealing Test commercial|seal testing methods pdf